QUICK TOUR

MachineConnectivity

We have everything you need in order to bring the intelligence to your machinery. Those are: knowledge, experience, know how and available engineers and technicians for the work to be done

YOUR PROJECT ROADMAP

Available documentation of machinery inspection

Related to the purpose of the project, our engineers do the check-up of documentation and available communication solutions

Older machines do not support modern communication protocols, but we don’t leave them out of scope, since we possess knowledge to integrate every possible machine in the system

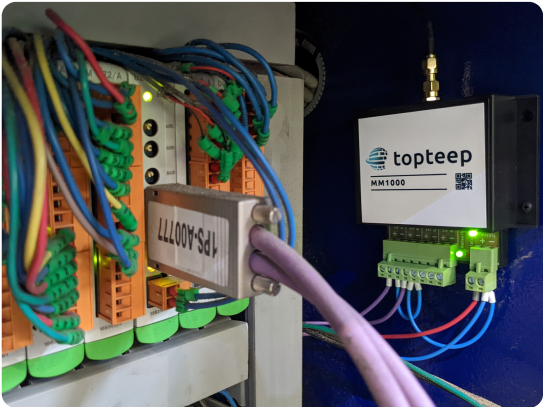

For communication with machine, we cover all available communication protocols and machine connection methods (PLC, OPC UA, ModBus, RS485, I/O modules, sensors, cameras)

Key benefit: all work is done by us. We lover the risk for the project by accepting responsibility of one-partner.

Fleet configuration

We prepare all IoT devices and infrastructure in our house, so we roll out installation on site

We help our clients lean their value chain. That is why we believe we have to optimize our value chain continuously

QA of devices is done in house, which lower the risk of equipment failure on site

Key benefit: everything set for the installation and that is why we claim the fastest time to market and zero error policy.

Installation on site

Our skilled technicians are trained for your company health and safety polices and they act professionally and only in scope of the project

Implementing all external activities so the clients process is not interrupted. Still, we need short shut downs when releasing IoT devices in work

Key benefit: your industry is very strict and all you don’t need is another external contractor doing work in and around your process on the shop floor.

IoT devices

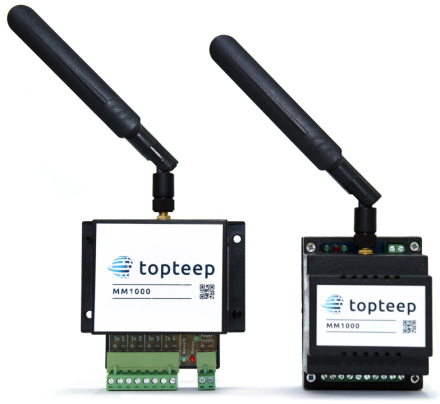

Innovative technologies enable modern IoT devices that acts in the same time as data acquisition device and gateway which communicates with the platform

We developed our own hardware for collecting data from the machine and communication with the platform

Our device is an industrial IoT module, acting as a micro-computer, capable for digital/analog signal acquisition and remote control and management. is based on modern SoC (System on Chip) microcontroller, which is developed to get D/A signals from machines and equipment. This super easy to install and affordable end-point device brings data from variety of actuators and sensors, delivering information about:

- Machine status

- Cycle speed

- Flow

- Material consumption

- Temperature

- Humidity

- Energy consumption

- Pressure

AM 1000 is is a smart meter designed for power supply system, industrial and mining enterprises and utilities to calculate the electricity consumption and manage the electric demand.

It features the high precision, small size and simple installation. It integrates the measurement of all electrical parameters with the comprehensive electricity metering and management provides various data on previous 48 months, checks the 31st harmonic content and the total harmonic content, realizes the remote communication and the remote control with switching input and relay output and boasts the alarm output.

It is fitted with RS485 communication port and adapted to MODBUS-RTU. AM 1000 can be used in all kinds of control systems, SCADA systems and energy management systems. The meter meet the related technical requirements of electronic meter in the IEC62053-21standards.

Easy and fast connect machines on our web platform for machine monitoring and manufacturing process management