FEATURES

TopPlan

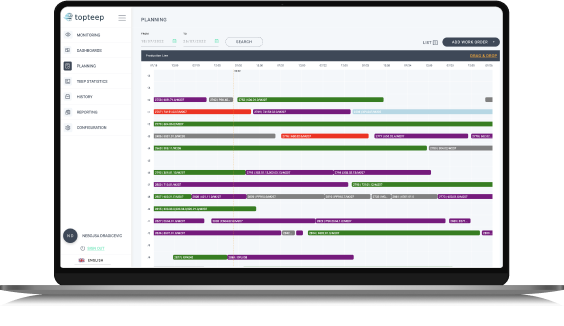

Planning and scheduling production process with our advance planning solution.

Fundament of every efficient manufacturing process is the ability of advanced planning and scheduling. With our TopPlan module, usage of capacity is optimal, since you monitor the execution of plan in real time.

Supported with smart algorithms, you are able to react fast and optimize the execution. With drag-and-drop interface and with full information in real time, you can easily move work orders around, while other work orders are automatically optimized and rescheduled.

PLANNING

Problems we solve

with advance planning and scheduling module:

If you are missing visual information about your plan, so you are not able to get instant information about timeline of work orders, is it started, when is started, when it will be finished. Instant information with just a look into visuals, reduces time for obtaining information for more then 30%;

If your clients are used on day-to-day ordering system and you want to remain flexible and able to answer optimal on those orders. Changes in production plan are optimized fast and smooth, so time necessary for changes is reduced for more than 50%;

Time lines and dead lines, regarding “just in time” philosophy, are high demands that come from our clients. The quality of your company is evaluated not only with the quality of your product, but with on time deliveries and system that can provide accurate information fast. TopPlan helps your planning department to observe easily production plan, execution and possible deviations in confirmed deliveries;

If you are aware of potential for saving time regarding change-overs and your team is focused on “external activities” preparations and SMED methodology, you need tight information on all interest parties at the same time, easily distributed. We help you synchronize teams and interest parties around change-overs, so everything is prepared on time and change-over is executed optimal;

Your sales is under pressure of obtaining information for their customer, especially if dead line is not going to be achieved. Often queries about plan execution, respecting “just in time” principle, can be managed fast and with almost no effort and time consumption of responsible people in planning department. Give some more space to planners and production responsible people, by acquiring information directly and not involving middle-man.

Do people in company spend time to agree about maintenance schedule and activities? Maintenance on the shopfloor impacts productivity and synchronisation of all interest parties is very important. TopPlan and its Advance planning and scheduling module enables that all activities related to shop floor are visible and transparent. We make sure everybody have information on time.

ACHIEVEMENTS

Our clients achieve

Without modern, digital solution for planning, production process is not fully optimized. The system automatically calculates and adjusts production times, machine occupancy and predicts execution times with its sophisticated AI built in solution.