FEATURES

TopSpeed

Speed up your cycle time by receiving information about slowdowns in real time.

Everybody run. Everybody play the game. It was never easier to cross the enterance barrier for industry and start doing business.

Our clients who have strategy of cost leadership, are after every part of a second. They need tools to fight slowdowns in their process. That is why we monitor speed of process with 2 digits in a second and have special plan for using our solution in order to stay on track with planned cycles.

MONITORING

Problems we solve

One of the main indicators of showing necessity for higher efficiency of manufacturing process is whether customers are asking for quantities that manufacturing process can’t deliver, or if the price on the market is not competitive. Usual waste in process which works against our clients is the speed of process and losses made with slower cycle speed. Topteep support for increase of competitiveness is through the solution of speed monitoring and alarming system if planned speed is missing. Our clients get notified in real time if the process is slowing down, so they can work on optimization immediately.

Sometimes, there are no resources to react on alarms that speed is slower than planned. If the optimization can’t be conducted in the very same moment, we remain constant with the information that the speed should be increased. We keep focused on the leakage as long as the client solve it or dismiss it as not possible to solve in this moment.

Some of the repairs in order to meet speed is not possible to solve while the machine is in progress, so we help our customers track the need for improvement when the production is finished. We provide valuable reports with speed analysis and enable comments during production in order to collect relevant data and not to forget important information. From all these activities, we help by enabling work order for maintenance creation

ACHIEVEMENTS

Our clients achieve

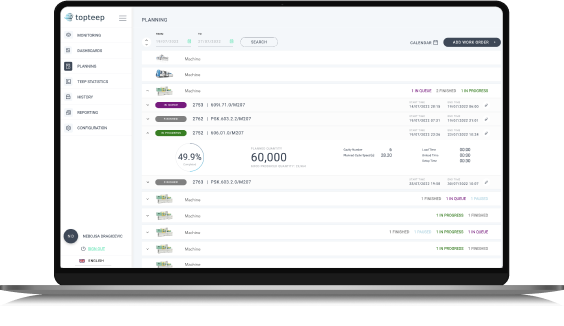

Without modern, digital solution for planning, production process is not fully optimized. The system automatically calculates and adjusts production times, machine occupancy and predicts execution times with its sophisticated AI built in solution.