FEATURES

TopOEE

Connecting with machines and gathering data directly

By connecting with the machinery, start monitoring your factory performance with real-time data. With just monitoring, your manufacturing process becomes more responsive.

That is where the progress starts. Making decisions based on real-time data and predictive algorithms increases efficiency further more.

TOPOEE

Problems we solve with TopOEE:

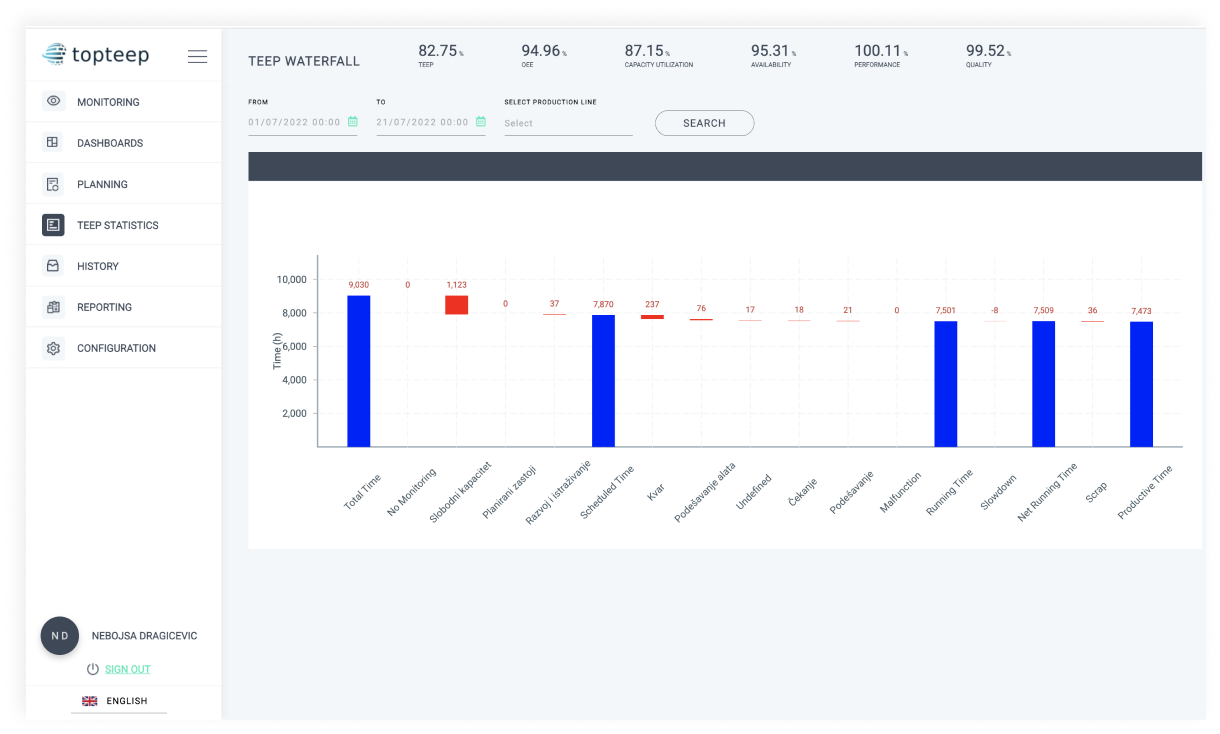

We install our own hardware on your machine, so we start monitor every activity and inactivity of the machine. This is for those manufacturing companies, who want to eliminate time necessary for collecting data about machine availability, performance and quality indicator, which is needed for calculating OEE. With this approach, it is possible to monitor OEE in real-time with our fast and responsive platform.

This is where real control starts.

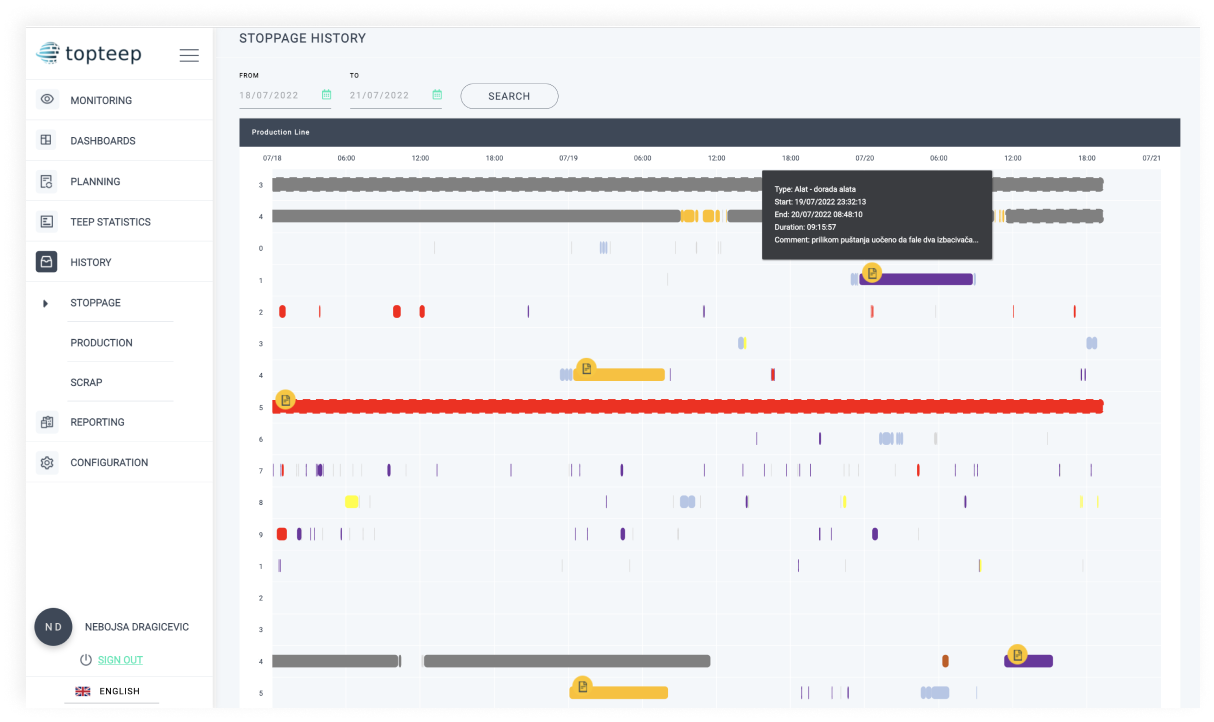

Our typical client wants to know immediately if execution of plan is not as planned. Plan execution is disrupted with stoppages, slowdowns and production of bad quality. Ultimate goal is to eliminate deviations, but first thing to do is to respond in the very same moment when they happen.

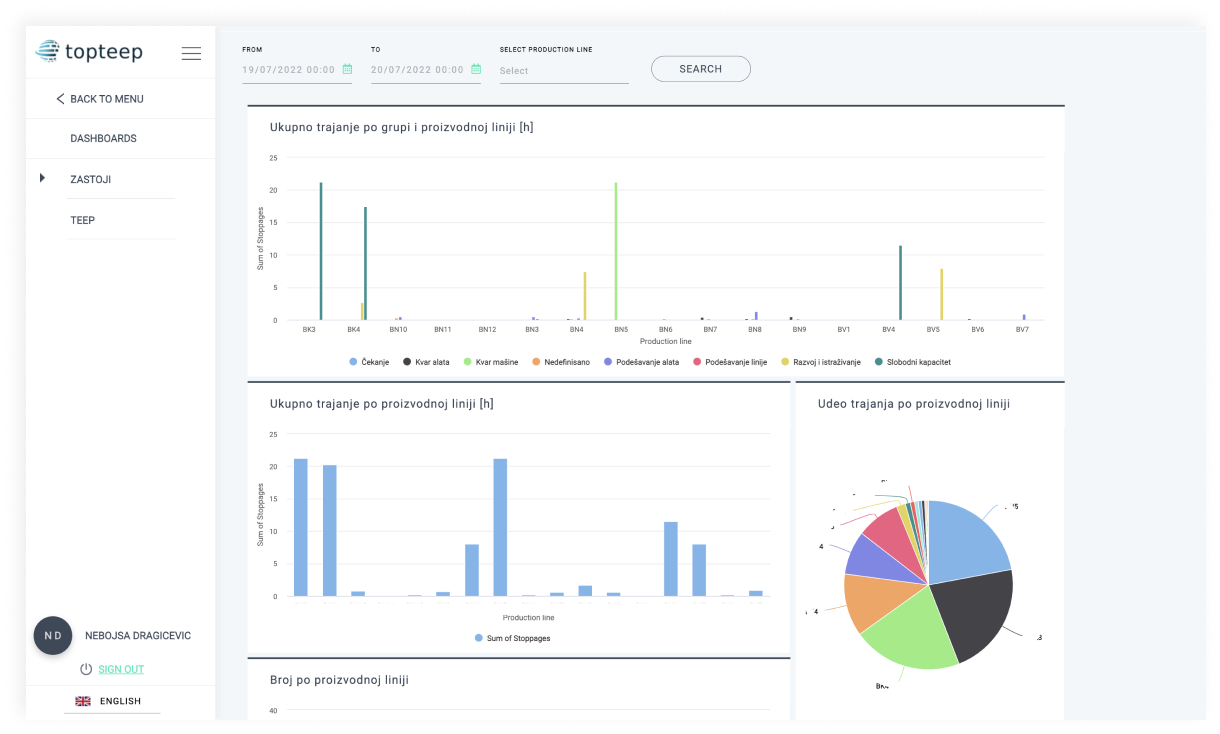

As soon as we get data, just throwing it on the end user is what concerns our clients the most. So, we work on every case, because every factory is its own “fingerprint”, optimizing visual data for users and valuable dashboards. Quick look into dashboards provides information necessary for decision making, up to 10 times faster then peeking into raw data and excel tables.

ACHIEVEMENTS

Our clients achieve

Without modern, digital solution for planning, production process is not fully optimized. The system automatically calculates and adjusts production times, machine occupancy and predicts execution times with its sophisticated AI built in solution.